Challenges of Dechlorination Control

Chlorine breakthrough can negatively affect your process and increase your operational cost. For example, Reserve Osmosis CPA membranes have an estimated chlorine tolerance of 1,000 to 2,000 ppm-hours before a doubling in salt passage occurs. The 1,000 ppm-hours level correlates to a chlorine residual in the RO feedwater of only 0.038 ppm for an operating period of 3 years! In a dechlorination process, carbon filters are notorious for breeding bacteria which can result in biological fouling of the RO membranes and piping network. Sodium Bisulfite also promotes Sulfur Reducing Bacteria (SRB) also leading to biological slime, reduced pH and malodor. These challenges are well known to require far more maintenance, effort and capital dollars to restore normal operation.

Ultra-Low Chlorine Measurement

An accurate measurement of chlorine level in the dechlorination process is necessary to enable rapid and actionable response to mitigate these issues. The measurement of chlorine in the ultra-low range must be fast, accurate, and robust. Membrane-based inline amperometry sensors respond slowly especially when chlorine concentrations are low and could take up to 24 hours before the sensor actually sees the chlorine signal. Well-known frequent maintenance issues increase the service cost and risk valuable assets. The conventional ultra-low chlorine inline colorimeter (i.e. HACH® CL-17) claims to measure as low as 0.008ppm (8.0ppb) of chlorine in water, but its discrete measurements every 2.5 minutes may limit its applications.

Pyxis Lab, Inc. ST-765 Sensor Performance

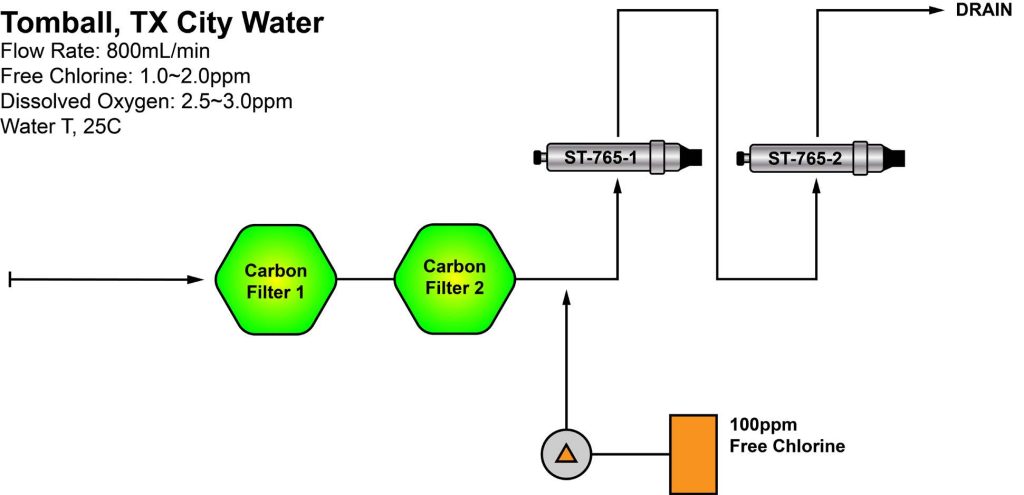

A lab study was designed as shown in the following diagram (Figure 1) to evaluate the performance of the Pyxis ST-765 free chlorine sensor at the level of “ultra-low” chlorine (i.e. <10ppb). In the test, two household carbon filters in series are utilized to remove free chlorine in the city water of Tomball TX. The water contains 1.0~2.0 ppm free chlorine. Its dissolved oxygen is in the range of 2.5-3.0ppm. The sample water runs at 800mL/min through the two carbon filters, ST-765-1, and ST-765-2 in series. The materials of the piping are Tygon and PVC. A peristaltic pump is used to inject a concentrated solution of free chlorine (100ppm) at 0.12 mL/min into the sample line right after the 2nd carbon filter. The two ST-765 sensors were pre-calibrated in the air for zero and at the sample of 500ppb of free chlorine for the slope.

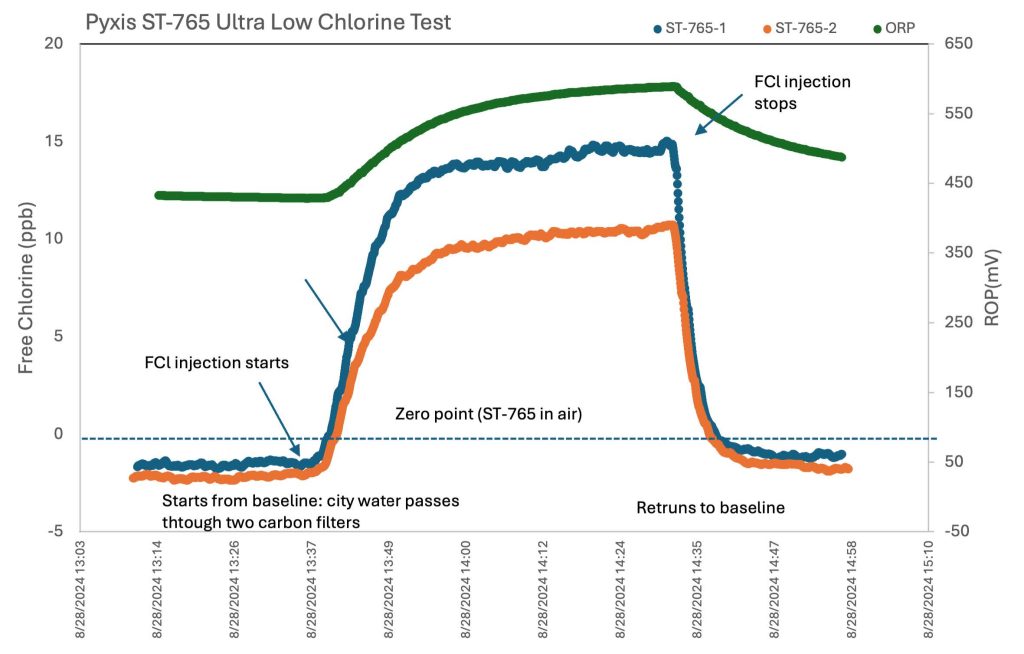

The measured chlorine concentrations in ppb from two ST-765 sensors and ORP value from the first ST-765 are shown in Figure 2 below. The test first establishes the baseline where all free chlorine is removed by the carbon filters. Once the concentrated free chlorine solution is injected, the signals of both sensors immediately start to rise, and plateau in about 17 minutes of measurement. The first ST-765 stabilizes at 13.8ppb, and 10.3ppb for the second one. The difference represents the chlorine demand due to the piping in between the two sensors. The signals drop rapidly and returns to the baseline shortly after the injection stops. One may notice that the chlorine demand in the piping slows down the rising of the chlorine concentration to a steady value but accelerates the reduction of chlorine concentration as it approaches the baseline. For comparison, the ORP is much slower to reach a plateau or return to the baseline, as also shown in Figure 2.

The limit of detection (LOD) of the ST-765 is determined from the baseline data to be 0.17 ppb (3 times of the standard deviation of the baseline). However, an amperometry sensor may read slightly differently when it is placed in air and in oxygen saturated DI water when zero calibration is carried out. As a result, there is an uncertainty in the zero point of the ST-765. This uncertainty could contribute a 0.5 ppb error in the ST-765 accuracy in the ultra-low range.

Conclusion

- The Pyxis Lab, Inc. ST-765 platform provides a unique and improved solution when compared to other commercially available sensors measuring for ultra-low chlorine in water continuously and in real time.

- The ST-765 technology can potentially initiate new opportunities in controlling dechlorination processes with more precision, minimizing operational cost and maximizing protection assets.